Scientists on the School of Illinois Urbana-Champaign have developed a cleaner and additional atmosphere pleasant strategy of recovering gold and platinum group metals (PGMs) from digital waste and totally different discarded provides.

Although it costs wherever from $925 to $4,500 to buy just one ounce of these treasured metals, gold and PGMs have specific properties that make them worth their extreme worth for electronics and clear energy utilized sciences.

Gold is extraordinarily conductive, does not tarnish or corrode, and is malleable enough to be made into ultra-thin wires and coatings for connectors, switches, relays, and contacts in electronics.

It is estimated that high-tech devices account for about 8% of gold’s normal demand.

PGMs – platinum, palladium, rhodium, ruthenium, iridium, and osmium – nonetheless, are extraordinarily valued for his or her catalytic abilities.

Given that mid-Seventies, platinum and palladium have been used to scrub air pollution from the exhaust of vehicles. As a result of the world transitions from fossil fuels to cleaner energy sources, the catalytic properties of PGMs are getting used to produce clean-burning hydrogen from water and totally different sources.

A School of Illinois Urbana-Champaign workers led by chemical and biomolecular engineering professor Xiao Su has developed an answer to selectively extract gold and PGM ions from a liquid containing dissolved e-waste, catalytic converters, and even ore from mining.

The way in which it really works

Xiao Su

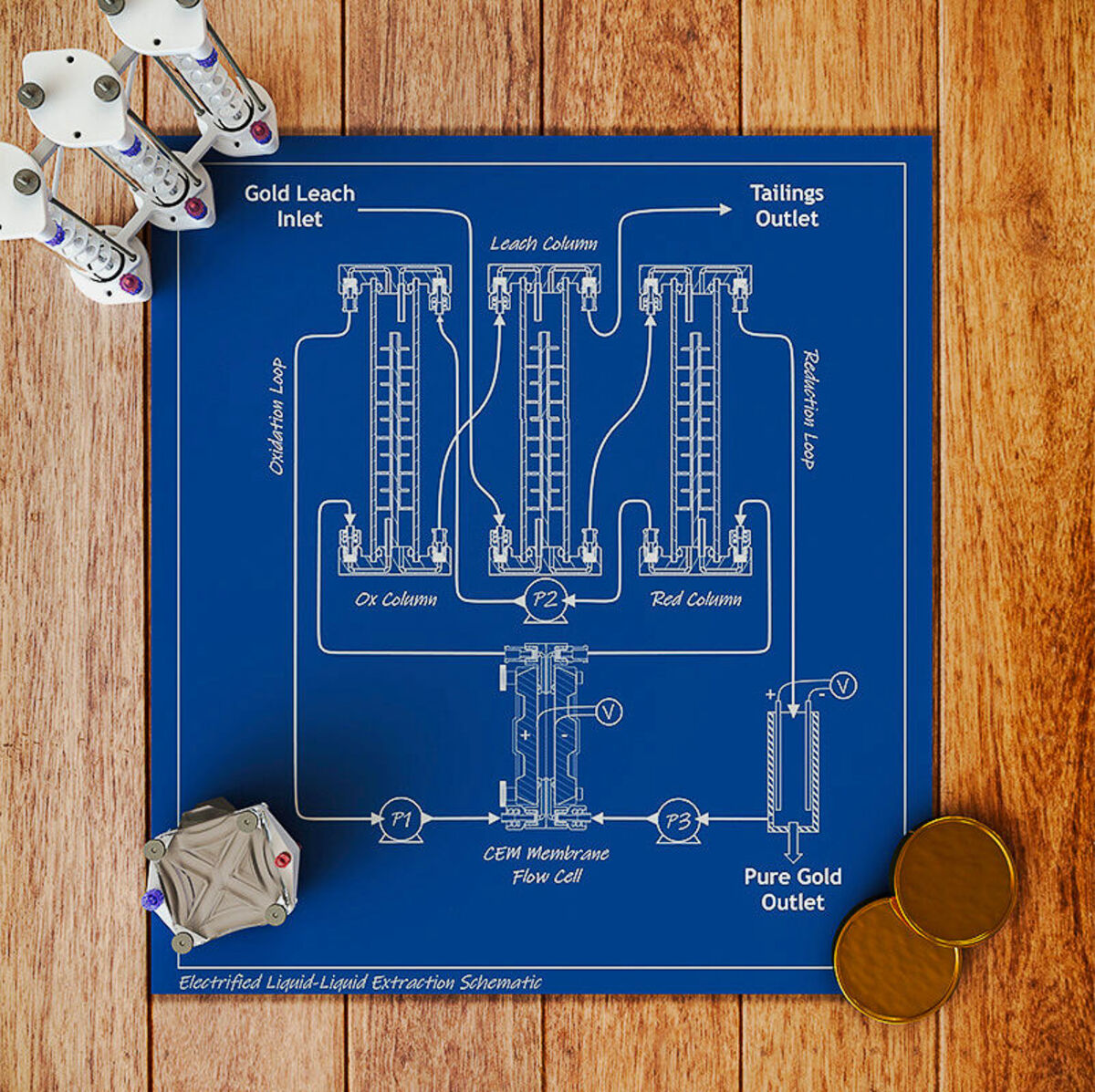

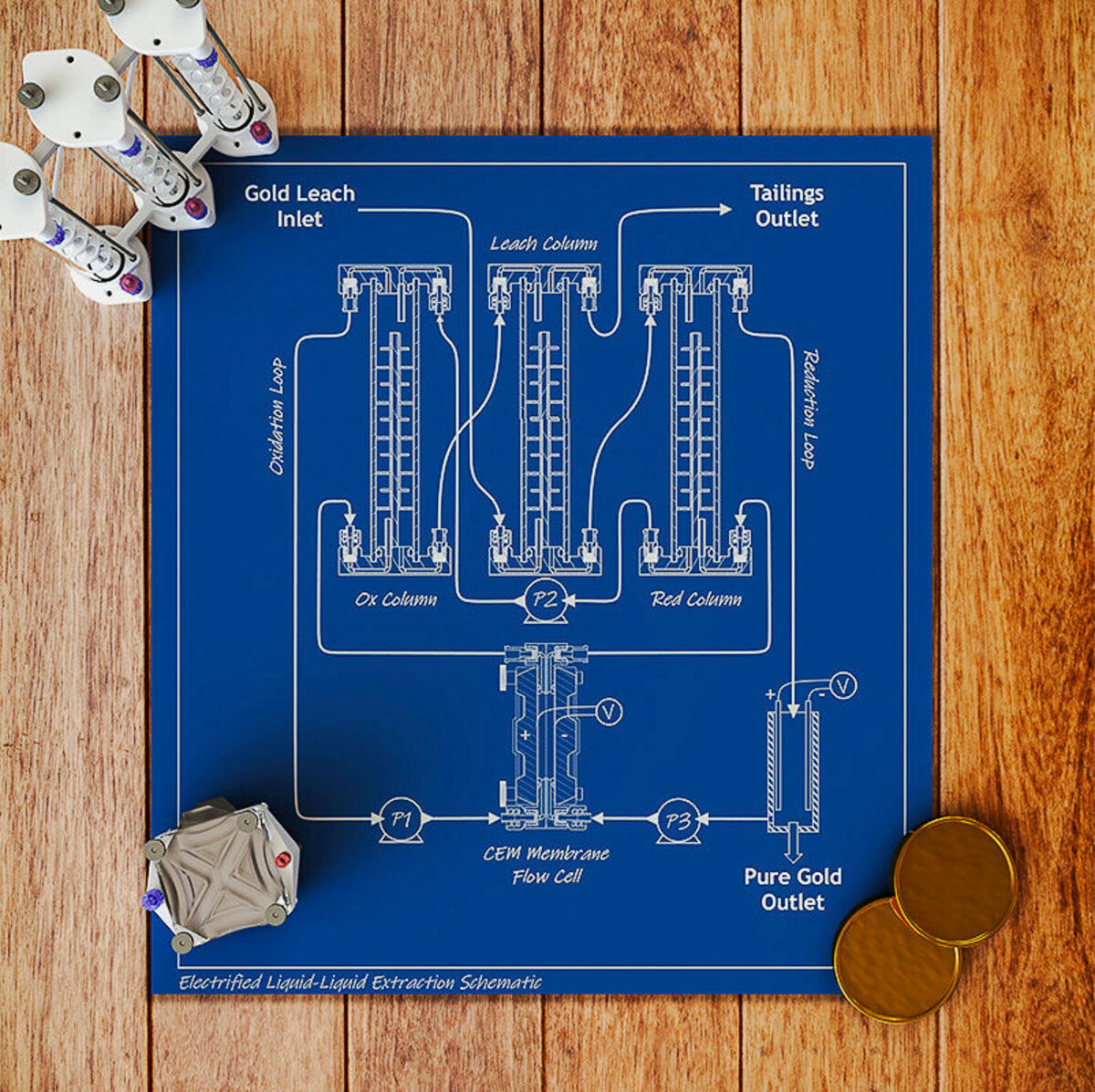

A schematic diagram detailing the electrochemical extraction machine used to extract gold in Professor Su’s laboratory.

The expensive metal extraction and separation course of developed by Professor Su and his workers is called electrochemical liquid-liquid extraction, or e-LLE.

“Our work is envisioned as a pathway in path of a broader class of industrially related liquid-liquid extraction-based electrochemical separations,” the researchers wrote in a paper revealed throughout the scientific journal Nature.

Inside the lab, the workers dissolved catalytic converters, e-waste, and simulated mine ores containing gold and PGMs using an pure solvent. The system then streams these dissolved electronics and totally different treasured metal-rich merchandise by three consecutive extraction columns – one for oxidation, one for leaching and one for low cost.

This method is able to selectively pull 90% of the dissolved gold and PGMs from the reply.

“The metals are then remodeled to solids using electroplating, and the leftover liquid could also be dealt with to grab the remaining metals and recycle the pure solvent,” Su talked about. “The stream containing the pure extractant is then pumped once more to the first extraction column, closing the loop, which enormously minimizes waste.”

Inexperienced gold and PGMs

An monetary analysis demonstrates that the model new method runs at a price of two orders of magnitude lower than current industrial processes. This may significantly improve the economics of recycling treasured metals. It is estimated that 90% of the gold utilized in electronics throughout the U.S. winds up in landfills as a substitute of recycling providers.

“The social value of this work is admittedly its talent to produce inexperienced gold shortly in a single step, enormously enhancing transparency and perception in conflict-free recycled treasured metals,” talked about postdoctoral researcher Stephen Cotty, the first creator of the analysis.

This extraordinarily atmosphere pleasant and clear strategy of pulling treasured metals out of dissolved waste and ore moreover happens to be extraordinarily selective, which suggests an virtually pure product is produced.

“We’re capable of pull gold and platinum group metals out of the stream, nonetheless we are going to moreover separate them from totally different metals like silver, nickel, copper and totally different a lot much less useful metals to increase purity enormously – one factor totally different methods battle with.”

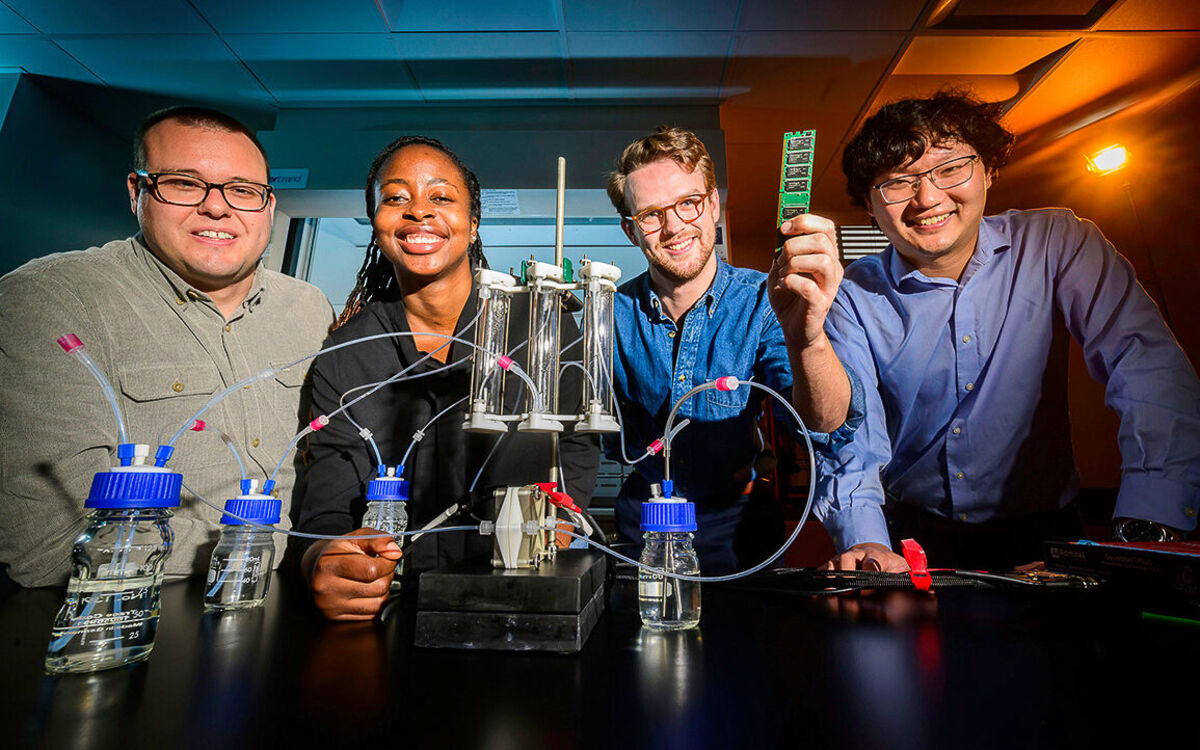

Fred Zwicky

School of Illinois Urbana-Champaign researchers (left to correct) Johannes Elbert, Aderiyike Faniyan, Stephen Cotty, and Xiao Su.

The School of Illinois Urbana-Champaign workers is working to good this treasured metals restoration method by enhancing the engineering design and solvent alternative.

The U.S. Division of Vitality supported this work.