EcoHoist’s lateral pondering within the case of rising a cheap reply for the vertical transport of material out of underground mines has drawn the attention of Mining One, an Australia-based consultancy company for the mining sector.

“Guaranteeing protected and setting pleasant haulage underground is popping into increasingly more tough,” talked about Gary Davidson, principal mining engineer at Mining One. “Our commerce ought to uncover lateral pondering approaches which will end in substantial enhancements in haulage effectivity.”

It was any such lateral pondering that led the workers at EcoHoist to develop a material hoisting system that is cheap to assemble and performance than the skip hoist strategies which have been traditionally used to maneuver ore and totally different provides to the ground at underground mines.

The potential of the EcoHoist system to significantly reduce the capital and operation costs at underground mines has already attracted the curiosity of ABB Group, a worldwide market chief in mine electrification, automation, and hoist strategies.

“Regardless of the mine in Australia, the issue is tips about methods to get ore out of the underside safely and successfully with extreme availability in very distant locations,” Aaron Trueman, Australian enterprise line supervisor for hoisting at ABB, talked about all through an April announcement that the Swedish company will collaborate on the occasion of EcoHoist. “Hoists are a important mine asset to achieve this, and novel approaches to ore haulage equal to EcoHoist are what the commerce should ship minerals vital to trendy know-how.”

Now, Mining One is lending its underground mining expertise to the occasion and early deployment of the EcoHoist system.

“Mining One is delighted to be involved inside the collaboration and validation of EcoHoist’s know-how, and we take enjoyment of contributing to the occasion of the quite a few advantages it may convey,” talked about Davidson.

Lateral pondering

Whereas there have been incremental enhancements to mine hoists over the earlier 150 years, the thought is way the an identical as a result of the steam-powered ore lifting strategies first launched inside the 1870s. The important idea behind standard mine hoists is {that a} large motor lifts skips, which can be containers used to maneuver provides, up large vertical shafts.

EcoHoist

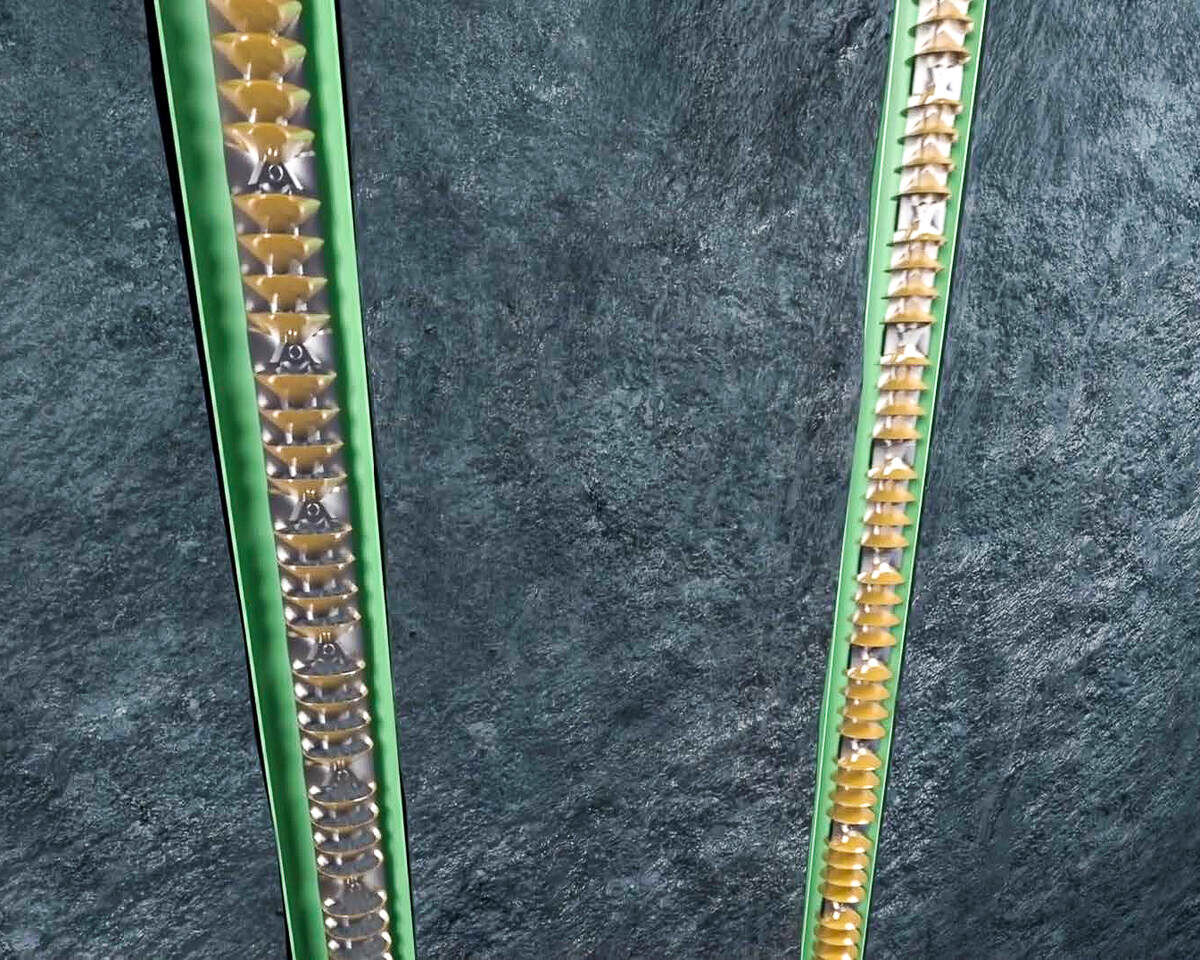

The EcoHoist bucket elevator solely requires two small mine shafts to maneuver supplies.

EcoHoist’s lateral pondering technique to lifting provides out of underground mines contains the choice of the usual skip hoisting strategies with a gentle bucket design that significantly reduces the scale of the mine shafts wished to maneuver the an identical tonnage of ore to the ground.

The EcoHoist system features a regular chain of recent buckets that lifts crushed supplies from depths of as a lot as 2,000 meters (1.2 miles) by a small vertical shaft and dumps the material on the ground sooner than the chain of buckets descends a second shaft.

The two 0.75- to 1.2-meter (2.5 to 4 toes) shafts wished for EcoHoist, counting on tonnage requirements, are significantly smaller than the five- to eight-meter (16 to 26 toes) mine shaft required for the standard skip hoist system capable of transferring the an identical amount.

EcoHoist

The EcoHoist bucket design permits extreme amount transport by small shafts.

The conical geometry of the buckets allows them to be loaded quickly and symmetrically so that no help other than the central linkage is required for stability. Consequently, there is no such thing as a such factor as a need for added structural help or alignment rollers.

Furthermore, the EcoHoist doesn’t require an expensive headframe like a skip hoist.

This equates to lower capital costs to excavate the smaller shafts and arrange the hoisting infrastructure. And updated analysis signifies that the charge to perform EcoHoist is lower than working just one underground mine truck.

Consequently, EcoHoist’s reply has the potential to lower the monetary hurdles for underground mines, whereas on the same time rising manufacturing and reducing emissions.

“EcoHoist presents a chance for mining leaders taken with integrating a low-cost reply into their operation,” Michael Fast, enterprise enchancment engineer at EcoHoist, talked about earlier this 12 months.

Mining One lends expertise

Making a step-change in the way in which wherein supplies is hoisted out of underground mines would require a minimum of some inside the mining sector to be ready to make that leap with the inventor.

ABB, which outfitted the first electrical motor for a mine hoist in 1891, has already joined EcoHoist in accelerating the deployment of the trendy hoisting concept.

Now, Mining One is lending its underground mining expertise to the EcoHoist vertical supplies transport reply.

EcoHoist

Mining One’s technical expertise will assist in integrating the EcoHoist vertical supplies transport reply into underground mines.

The worthwhile arrange of an EcoHoist system into an underground mining mission requires engineers to take many components into consideration. The shape and measurement of the orebody being mined, geotechnical conditions, and the overall mine web site format are among the many many technical components that should be taken into consideration.

As a longtime mining consultancy company with initiatives on six continents, Mining One brings deep technical expertise and experience to the deployment of EcoHoist’s low-cost hoisting gear.

“In order to effectively decarbonize and decrease operational costs for our shoppers, our EcoHoist gear should be seamlessly built-in into our shoppers’ mines,” talked about EcoHoist Managing Director Matthew Forrest. “Working with Mining One provides every us and our shoppers confidence that this may be achieved.”

As an early collaborator on EcoHoist’s trendy and monetary reply to vertical ore transport, Mining One is poised to develop to be the first accredited advisor for this economical vertical supplies transport reply.